Are you one of the many people in Miami who suffer from foot problems? From plantar fasciitis to flat feet, foot pain can be a frustrating and limiting experience. But have you considered custom orthotics? These specially-made shoe inserts can provide the extra support and cushioning your feet need to alleviate pain and improve mobility. The Southernmost Foot and Ankle Specialist health care professionals are experts in choosing the proper technique and materials for your custom orthotics to help your foot condition. In this article, we’ll explore the techniques and considerations involved in making custom orthotics in Miami.

Custom orthotics are shoe inserts that are specially designed and manufactured to meet the individual needs of a patient’s foot. They are designed to address specific foot problems or injuries, improve foot function, and enhance comfort and performance during activities like walking, running, and sports.

Custom orthotics, as opposed to over-the-counter shoe inserts, are manufactured to fit the individual’s specific foot form, foot condition, and biomechanical needs. They are prescribed by a podiatrist or other healthcare provider after a thorough evaluation of your feet and lower extremity function. Plantar fasciitis, flat feet, high arches, heel pain, arthritis, and other ailments can all be treated with them.

Benefits Of Custom Orthotics

Custom orthotics are specially designed devices that are made to fit an individual’s feet and address specific foot and lower limb conditions. Here are some of the benefits of custom orthotics:

- Provides Proper Support: Custom orthotics are designed to provide the necessary arch support, helping to correct foot and lower limb alignment issues that can cause pain and discomfort. This support can help improve posture, reduce muscle fatigue, and prevent future injuries.

- Reduces Pain: One of the primary benefits of custom orthotics is their ability to relieve pain and discomfort. By correcting foot alignment issues and reducing pressure on specific areas of the feet, custom-made orthotics can help alleviate pain associated with conditions such as plantar fasciitis, flat feet, and arthritis.

- Improves Mobility: Custom orthotics can improve mobility and make it easier for individuals to move around without experiencing pain or discomfort. This can be especially important for athletes and active individuals who want to maintain their level of activity without being limited by foot pain or injuries.

- Enhances Athletic Performance: Custom orthotics can be designed to improve athletic performance by providing additional support, stability, and shock absorption to the feet. This can help reduce the risk of injury and improve overall performance.

- Reduces The Risk Of Developing Foot Problems: By correcting foot alignment issues and reducing pressure on specific areas of the feet, custom orthotics can help reduce the risk of developing foot problems such as bunions, corns, and calluses.

- Improves Quality Of Life: Custom orthotics can greatly improve the quality of life for individuals who suffer from foot and lower limb conditions. By reducing pain, improving mobility, and enhancing athletic performance, custom orthotics can help individuals live a more active and fulfilling life.

The Techniques For Making Custom Orthotics

There are several techniques used for making custom foot orthotics, each with its own advantages and disadvantages. Here are three common techniques for making custom orthotics:

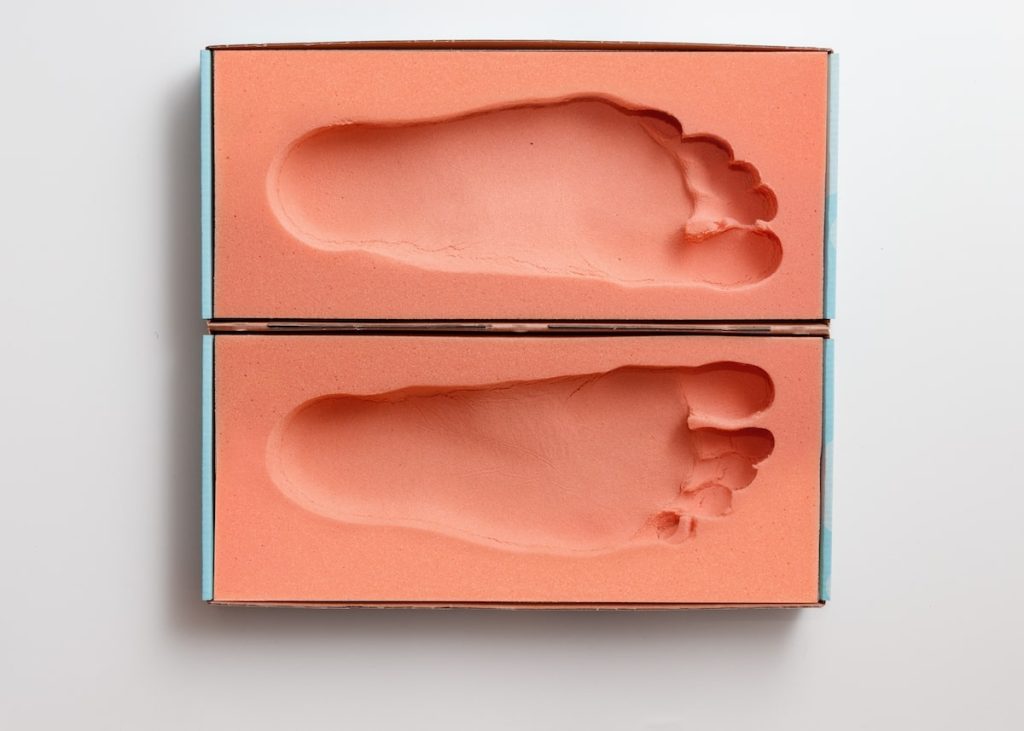

- Foam Casting Technique: This technique involves using a foam impression box to take an impression of the patient’s foot. The impression is then sent to a laboratory where a custom orthotic is fabricated using the impression as a mold. However, it may not be as accurate as other techniques, and the foam can compress, leading to a less precise fit.

- 3D Printing Technique: This technique involves using a 3D printer to create a custom orthotic based on a digital scan of the patient’s foot. The scan can be taken using a laser scanner or by using a smartphone app that takes photos of the foot. The advantage of this technique is that it allows for a high level of precision and customization, and the orthotic can be printed quickly.

- CAD/CAM Technique: This technique involves creating a custom orthotic utilizing computer-aided design (CAD) software and computer-aided manufacturing (CAM) technology. A digital scan of the patient’s foot is taken, and the orthotic is designed using CAD software.

The design is then sent to a milling machine, which uses CAM technology to carve the orthotic out of a block of material. The advantage of this technique is that it allows for precise customization, and the orthotic can be made quickly. However, it can be costly, and the availability of CAD/CAM technology in some locations may be limited.

The Custom Orthotics Fitting Process

The orthotics custom fit process involves several steps to ensure that the patient’s foot condition is accurately diagnosed and that the orthotics are tailored to fit their individual needs. The standard steps in the custom orthotics fitting process are as follows:

- Foot Condition Analysis of the Patient: A comprehensive evaluation of the patient’s foot condition is the first step in the fitting process. A physical examination of the feet and lower legs, as well as a review of the patient’s medical history and any imaging procedures, such as X-rays or MRIs, may be performed.

- Casting Or Foot Scanning: Once the type of orthotic has been determined, the patient’s feet are casted or scanned to create a mold of the foot. This can be achieved through a variety of techniques, such as traditional plaster casting or computer-aided design (CAD) scanning. The orthotics provider will ensure that the patient’s foot is held in the correct position during the casting or scanning process to ensure an accurate fit.

- Creation Of The Custom Orthotic: Once the mold of the patient’s foot has been created, the orthotic is manufactured. This process typically involves the use of specialized materials and manufacturing techniques to ensure that the orthotic is durable, functional, and comfortable for the patient to wear.

- Adjustment And Fitting Of The Orthotic: After the custom orthotic has been manufactured, it is fitted to the patient’s foot. The orthotics provider will make any necessary adjustments to the orthotic to ensure that it fits properly and provides the appropriate support for the patient’s foot condition. This may involve trimming the orthotic, adding padding, or making other modifications to ensure a comfortable fit.

- Follow-up Appointments: After the fitting of the orthotic, the patient will often have follow-up appointments with the insoles provider to check that the orthotic is functioning correctly and that any difficulties or concerns are addressed. In some cases, additional adjustments may be necessary to ensure optimal comfort and effectiveness.

Considerations For Choosing The Right Technique

Several considerations should be addressed while selecting the best technique for producing bespoke orthotics to guarantee that the method is effective and appropriate for the patient’s needs. Here are some of the most important considerations:

- Accuracy: Accuracy is a critical factor to consider when choosing a technique for making custom orthotics. The technique used should be precise enough to create an orthotic that fits the patient’s foot correctly and addresses their specific foot problem. The precision of a procedure varies based on the patient’s condition, the materials utilized, and the experience of the person manufacturing the orthotic.

- Cost: Cost is another important factor to consider when choosing a technique for making custom orthotics. Different techniques can vary significantly in cost, from relatively inexpensive foam casting to more expensive 3D printing and CAD/CAM methods. The cost of the technique should be balanced against the benefits it provides and the patient’s budget.

- Time Efficiency: Time efficiency is also a factor to consider, especially if the patient requires their custom orthotics as soon as possible. Some procedures, such as foam casting, may take less time to complete than others, such as 3D printing, which might take many hours or even days.

- Customizability: Customizability is another critical consideration when choosing a technique for making custom orthotics. Different techniques may offer varying levels of customization, with some techniques allowing for more intricate designs and adjustments than others.

- Availability Of Equipment And Patient Preferences: Availability of equipment and training is another important factor to consider when choosing a technique for making custom orthotics. Patient preferences should also be taken into account when choosing a technique for making custom orthotics. Patients may choose one technique over another based on criteria such as their degree of comfort, previous experience, or the recommendation of their healthcare professional.

Custom orthotics can be created to match the particular demands of patients using modern techniques and considerations, giving them the appropriate level of support and correction to alleviate pain, increase mobility, and enhance athletic performance. By working with a qualified orthotics provider, patients can enjoy the many benefits of custom orthotics and live a more active and fulfilling life.